Strain Gauge Testing Lab

Experimental stress analysis is based on the principle of strain measurement. Initially, bulky mechanical devices were used for measuring strain that displayed strain using a lever ratio of one thousand or more. These devices were the only type available for performing measurements so essential for stress analysis.

Normally, the strains determined with strain gauges are very small. The change in resistance is also minimal and direct measurement is not possible.

The strain gage must be included in a measurement system where accurate determination of the strain gage's change of resistance is possible.

The components include a strain gauge, which converts mechanical strain into a change in electrical resistance and a measuring circuit that is shown as the Wheatstone bridge having the strain gage as one arm.

Both the measuring circuit and the strain gauge are passive components. When the strain gage's resistance changes due to a strain, the bridge circuit loses its symmetry and loses its balance. A bridge output voltage is obtained which is proportional to the bridge's unbalance.

The measuring system includes an amplifier as the third component which amplifies the bridge output voltage to a level suitable for indicating instruments.

In some cases amplifiers are designed to give an output current proportional to the bridge output voltage, but some models can provide either voltage or current outputs. The fourth component in the measuring system is the display. Here the output signal of the amplifier is converted into a form which can be understood by the user.

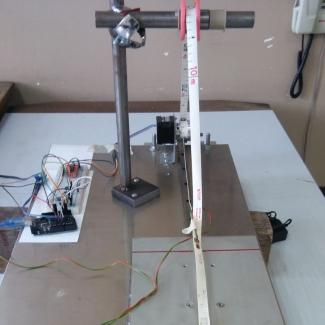

We provide strain gauge testing of mechanical components and structures. Strain gauges are devices used to determine material strain due to static and dynamic loads coming from internal and external sources such as mechanical, thermal and pressure. During a given test, a gauge is attached to the specimen by an adhesive bond. As the specimen is deformed by loading, the foil within the gauge is deformed, which causes the electrical resistance to change. Measurement of the gauge electrical resistance is performed using a Wheatstone bridge circuit and a computerized data logger.

We can bond strain gauges to the test surface, perform data acquisition and provide test data to assist in identifying the stress, mechanical failure or fatigue to verify design, uncover weak points, and/or validate your FEA. We have the the experience to assist in increasing every component reliability.