PhySiMaP-Lab

The PhySiMaP-Lab is part of the network of laboratories of the research group on Materials and Innovative Technology (SMATIgroup), which work in the scientific Area of Manufacturing Systems and Technologies. The network includes the laboratories of Advanced Forming & Manufacturing, Metallography and Microscopy, Optimization of Manufacturing Processes by Numerical Simulations, and Thermo-Physical Characterization of Post-Formats Polymers. The laboratories of the network are located di the DMMM, Viale Japigia 182 – Bari - Italy

Aim

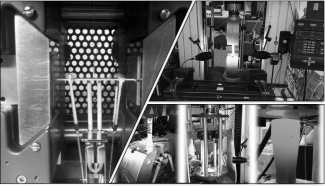

The PhySiMaP-Lab performs teaching, research and service activities based on the reproduction in a laboratory scale of a real-world manufacturing process or of the end use of a material. Thermal and mechanical cycles are imposed on small samples of the investigated material, using a commercial physical simulator (3185 Gleeble System) or in home designed equipment. The latter are designed integrating and controlling a Universal testing Machine (200kN - INSTRON 4485), a Digital Image Correlation software (Aramis), a gas pressure system and heating devices based on induction heating or electrical resistance heating. Knowledge acquired through this approach have be used in applications concerning process simulation, testing and basic material studies on steels and light alloys (titanium, aluminium and magnesium).

Skills

Supporting the SMATIgroup research activities, in the M&M-Lab have been developed skills on some process simulation applications, like heat treatments, hot deformation, gas forming, post weld heat treatment. Testing applications concern the determination of stress vs. Strain curves in cold, warm and hot condition, Creep/Stress Rupture evaluation, superplastic characterization, weld heat affected zone simulation for weldability assessment, determination of drawability, bendability, stretch-bendability and formability (by Marciniak and Nakazima test) in cold and warm condition (until 300°C). Application in basic materials studies concern work hardening, precipitation hardening and annealing.

Current research activity

Currently, the PhySiMaP-Lab is involved in research activities financed by the Italian Ministry of Education, Universities and Research Government and by private industry, aimed to the (i) experimental validation an the process analysis of new assembly technologies for the lightening of vehicle structures (Single-Side Resistance Spot welding, Friction Stir Spot Welding, Friction Element Welding, fiber laser welding). (ii) hot stamping of advanced high strength steel