Residual stress (RS) develops during manufacturing processes as a result of heat and mechanical treatment experienced by the material.

The TRASFORMA laboratory network includes laboratories of the Polytechnic of Bari, the University of Sal

The strong commitment of Politecnico di Bari towards manufacturing sustainability deploys into

the proactive promotion of social involvement of its students into the sustainability topics. The

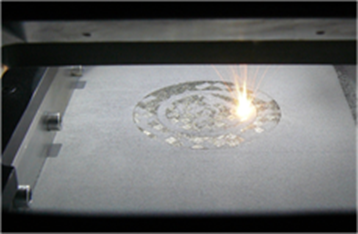

Since 2007, the Laboratory of Manufacturing processes by Laser Technologies (LLT) of Politecnico

di Bari has been working on Laser Additive Manufacturing processes of metals and on laser

micro-machining.

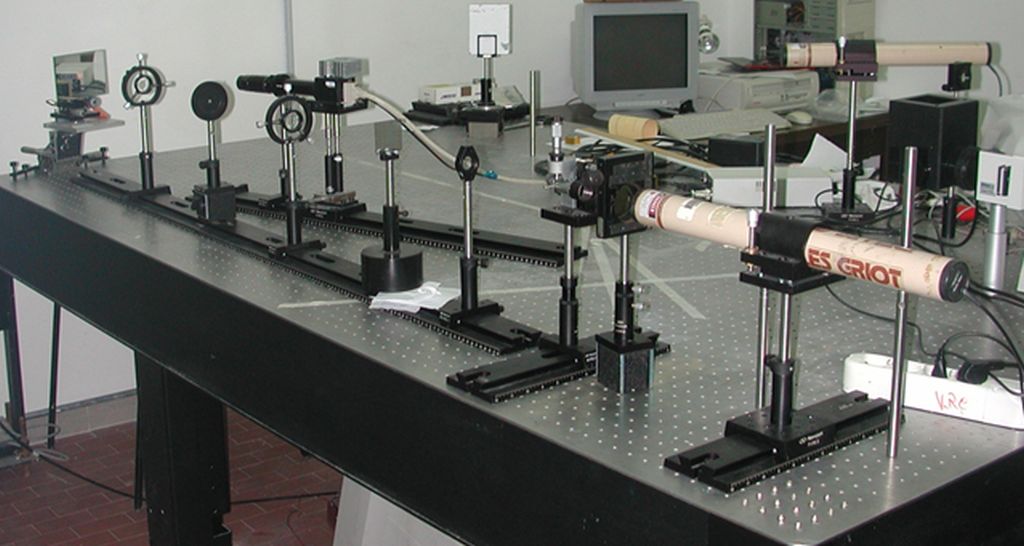

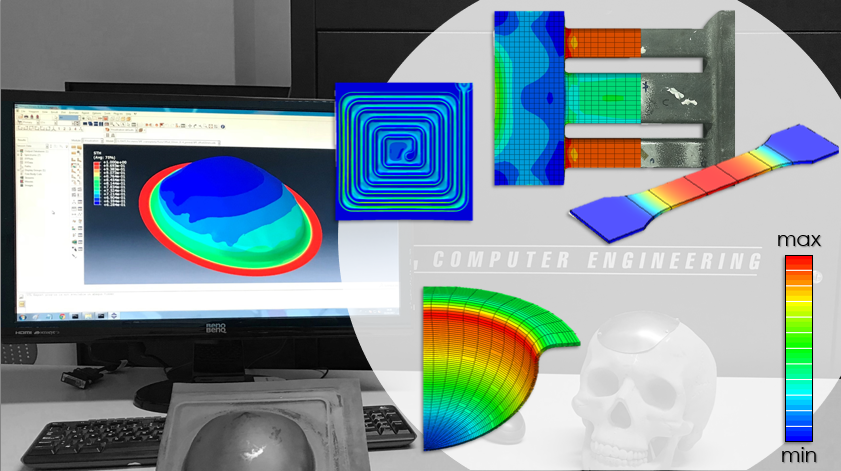

• Interferometric techniques (speckle, moiré and holography) are applied to stress/strain analysis

of electronic components, biological specimens and industrial components, reconstruction of

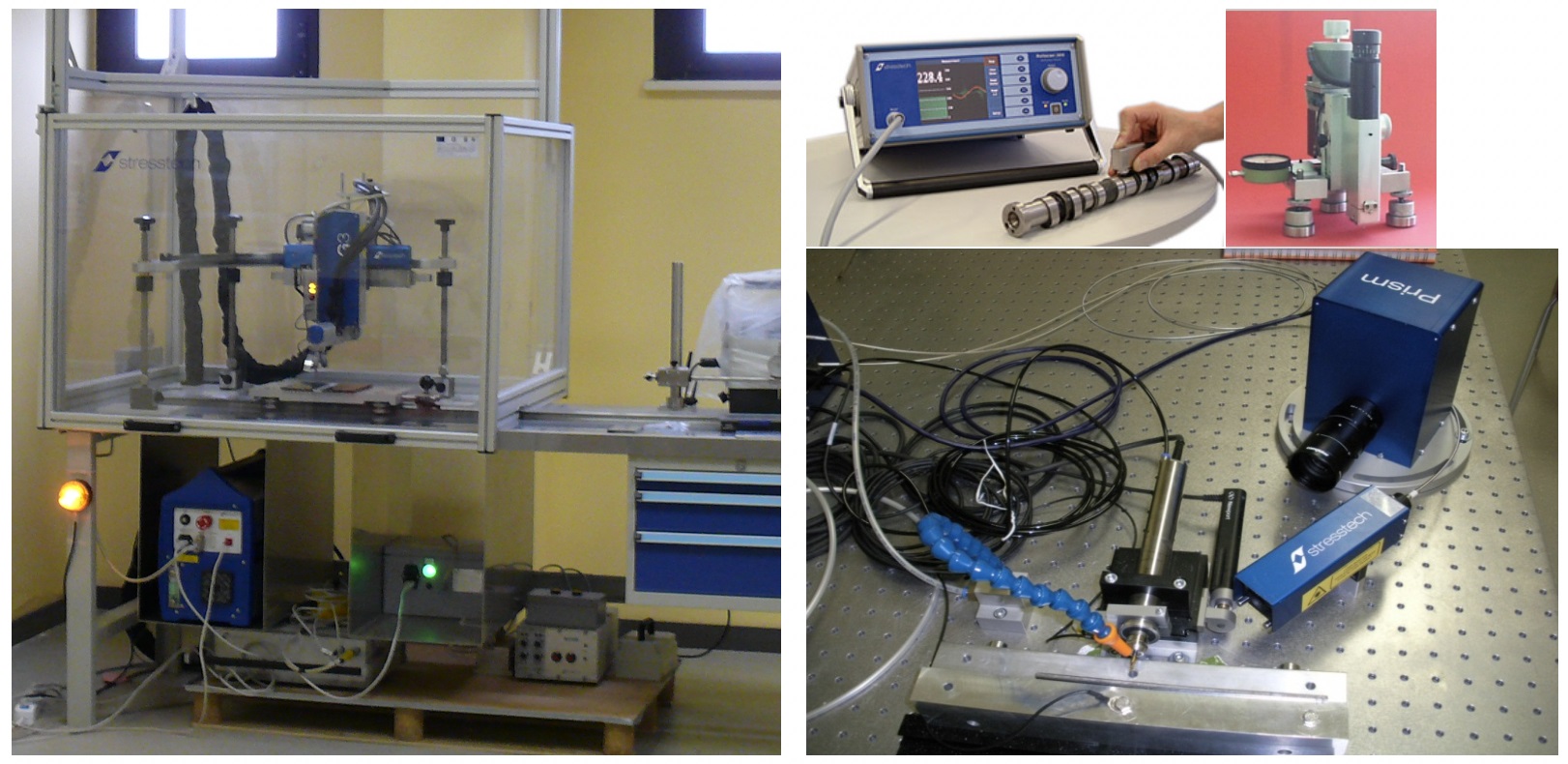

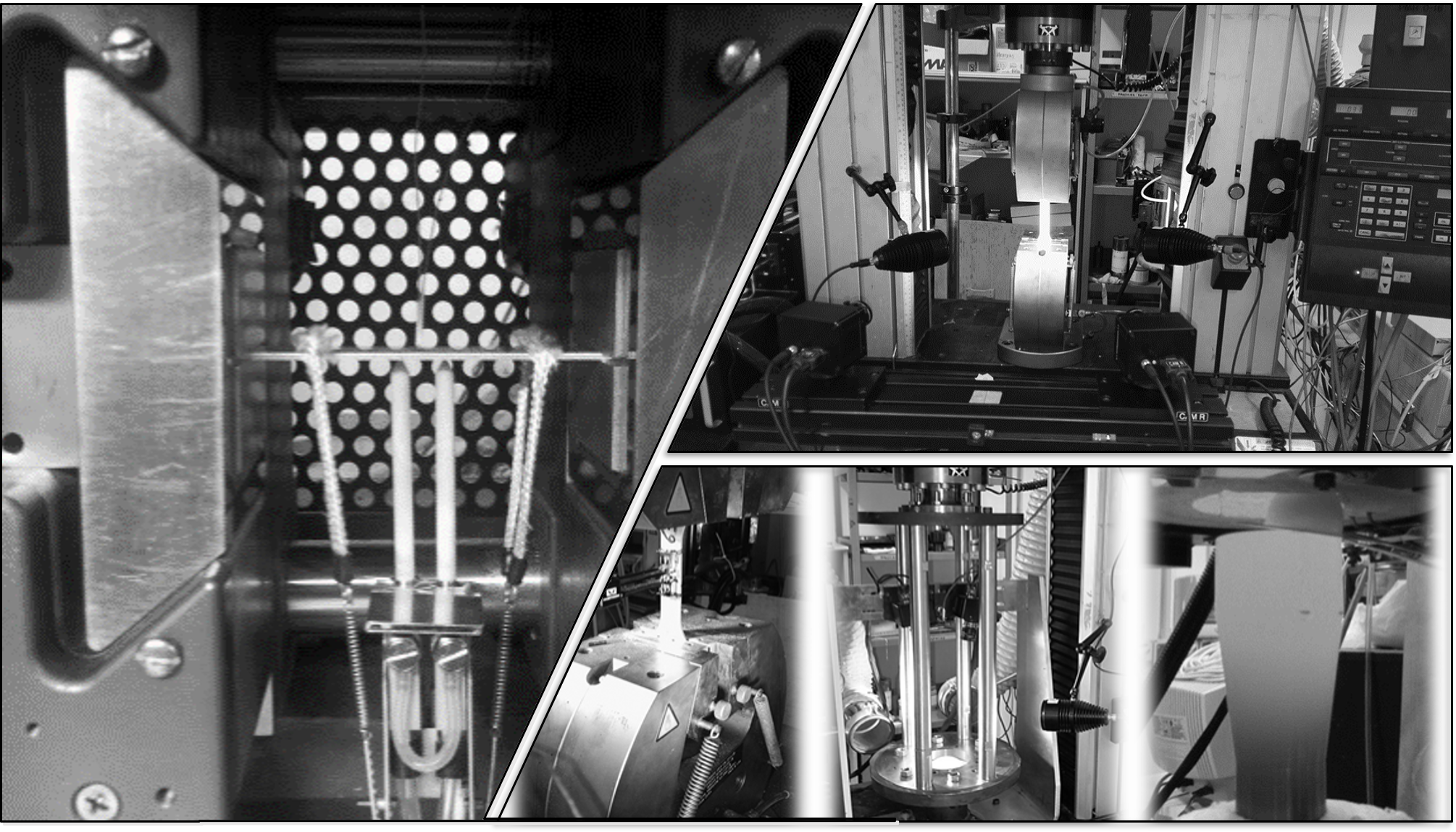

The research group working in the Experimental Stress Analysis laboratory, in the field of Experimental Mechanics, has developed wide experience for both in lab and in situ inspections, related to the stress/strain analysis on materials, component

Simulation models and mathematical programming techniques can deal with manufacturing systems which call for complex decisions concerning daily issues as well as middle and long horizon strategies (e.g.

The PhySiMaP-Lab is part of the network of laboratories of the research group on Materials and Innovative Technology (SMATIgroup), which work in the scientific Area of Manufacturing Systems and Technologies.

The lab ManOnSim is part of the network of laboratories of the research group on Materials and Innovative Technology (“SMATIgroup”) whose member operate in the scientific area Manufacturing Systems and Technologies (ING-IND/16).

The lab carries out research applied to the field of automated and robotic mechanisms and device.