ManOnSim Lab

The lab ManOnSim is part of the network of laboratories of the research group on Materials and Innovative Technology (“SMATIgroup”) whose member operate in the scientific area Manufacturing Systems and Technologies (ING-IND/16). The above mentioned network of laboratories is composed by the laboratory of: Advanced Forming & Manufacturing (AF&M-lab), Physical Simulation of Manufacturing processes (PhySiMaP-Lab), Metallography and Microscopy (OMM) and Thermo-Physical Characterization of Post-Formed Polymers. All the laboratories are located in Viale Japigia 182 – Bari – Italy (DMMM).

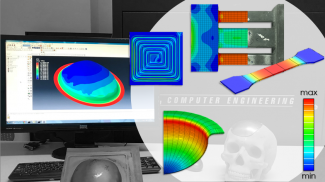

The lab ManOnSim is equipped with facilities suitable for the numerical simulation of industrial processes, like:

Sheet Metal Forming in warm and hot conditions;

Casting (sand and high pressure);

Surface treatment (laser hardening, laser remelting);

Heat treatment on steels and aluminum alloys;

Multiphysics processes (induction heating, electro magnetic forming, electric heating);

Residual stresses.

A numerical-experimental approach, based on the mechanical and deformative behavior (using the facilities in PhySiMaP-Lab and OMM-lab) and on the following experimental validation (using the facilities in the AF&M-lab), is adopted.

Both the model tuning and the optimal process conditions are obtained using multi objective optimization techniques based on genetic algorithms and the Response Surface Methodology.

Currently in the lab ManOnSim are conducted research activities financed by the Italian Ministry of Education, Universities and Research Government and by private companies aimed at simulating: (i) the SPF process for producing highly customized biomedical Titanium prostheses; (ii) the warm forming process for producing parts for railways applications; (iii) both the local heat treatment and the stamping process of aluminum heat treated blanks.